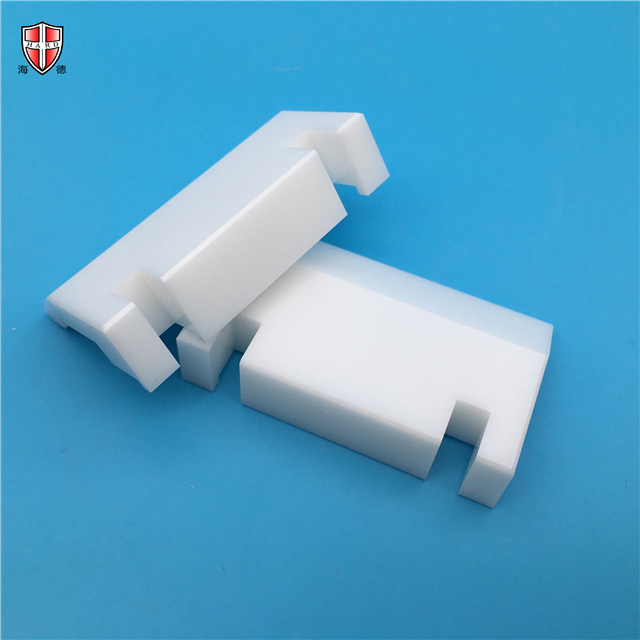

customized zirconium oxide ceramic machining block chunk

Reputation depends on quality, quality comes from Hard!

Zirocnia Ceramics:

Zirconia milling machine: It is a machine tool for milling workpieces with a milling cutter. In addition to milling planes, grooves, gear teeth, threads and spline shafts, milling machines can also process more complex profiles. The efficiency is higher than that of planing machines. It is widely used in machinery manufacturing and repair departments. Planer: A linear motion machine tool that uses a planer to plan the plane, groove or formed surface of the workpiece. The use Al2o3 Ceramic of planer processing, the tool is relatively simple, but the productivity is low (except for processing long and narrow planes), so it is mainly used for single-piece, small-batch production and machine repair workshops, and is often replaced by milling machines in mass Boron Nitride Ceramic production. According to the structure and performance, planers are mainly divided into bullhead planers, planer planers, single-arm planers and specialized planers (such as edge planers for planing the edge of large steel plates, planing punches and planers for complex-shaped workpieces). The bullhead planer is named after the ram and the Zirconia Ceramic Rings tool holder are shaped like bull's head. The planer is mounted on the ram tool holder for longitudinal reciprocating motion, and is mostly used to cut various planes and grooves. The gantry planer is named after a gantry frame structure composed of top beams and columns.

Data Sheet↓

Color: Customized Density: 6.0g/cm3 Zirconia Content: 94.4% Gas permeability: 0 Water Absorption: 0 Crystal Size: 0.5um Rockwell Hardness(45N): 78R45N Vickers Hardness (Load 500g): 11.5(1175)Gpa(Kg/mm²) Flexural Strength(20°C): 800Mpa Compressive Strength(20°C): 2000Mpa

Modulus of Elasticity(20°C): >200Gpa

Fracture Toughness(20°C): 9.0 MPam1/2 Thermal Conductivity(20°C-400°C): 2.5W(mK) Thermal Expansion Coefficient: 9.6 10-6/°C Thermal Shock Resistance: 250 △T°C

Application industry :

Machinery, fiber optic, knife, medical, food, petroleum etc.

Bestimmte Anwendung:

plunger, ceramic shaft, fiber optic bushing, stub, grinding, ceramic knife, ceramic slide guide, machined plunger, mobile phone shell, watch case, haircut razor blade etc.

Warum uns wählen? 1.12 years of professional production industrial ceramics factory 2.High quality products with low price 3.High precision parts with lowest tolerance 4.Short time for production 5.Has a group of experienced, professional and efficient R&D team 6.Has a good reputation in China and abroad. 7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.