The emergence of ceramic sheets, good decorativeness is loved by many people, what is the construction process of ceramic sheeting ? Today, we will learn the contents of the construction process of the ceramic thin plate together through the following contents.

Construction preparation of ceramic sheet construction process

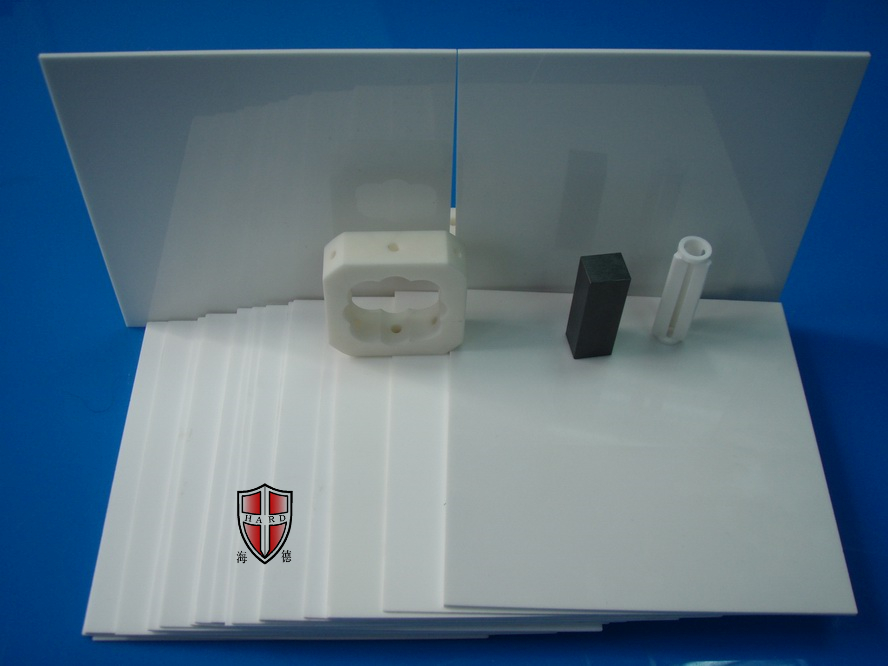

1. Material preparation: special adhesive for ceramic sheet (one-component), special adhesive for ceramic sheet (two-component)

2. Tool preparation: Mixing barrel, small gray shovel, sawtooth trowel, straight wood bar, pallet, level ruler, ink fountain, nylon thread, 2m by ruler plate, sprinkler shell, wire brush, long hair brush, small rubber hammer, Large plastic hammer and so on.

Ceramic plate construction process paving method

1. Wall wet hanging and paving: The construction process flow includes: base layer processing → elastic line separation → material preparation → thin plate adhesive surface cleaning → adhesive construction → thin sheet back coating → thin-sheet laying → surface cleaning and protection.

2. Surface wet paving: The construction process flow is as follows: grass-roots processing → bullet line → material preparation → laminating surface cleaning → adhesive construction → surface material back coating → surface material paving → flatness adjustment → surface Clean and protect.

3, wall hanging paste construction (24 meters above the outer wall): the construction process: thin plate back-affixed pendant pre-fixed → base processing → bullet line → material preparation → thin plate adhesive surface cleaning → adhesive construction → thin plate Back-coating → Thin-laying → Flatness adjustment → Fastening of fixtures and walls → Surface cleaning and protection.

Ceramic thin plate construction process construction method

The adhesive is evenly scraped onto the construction base with a serrated trowel, and the building ceramic sheet is then pressed into the adhesive in a kneading manner to form a strong adhesive layer with a thickness of 3-6 mm.

Construction Considerations of Ceramic Sheet Construction Process

1, but because ceramic thin bricks are much thinner than ordinary tiles, so the production process needs to be more advanced, and the construction is also very particular about, you should take care to avoid causing the tiles to crack during the construction process.

2. Prior to laying ceramic thin bricks, the foundation should be solid, smooth, clean, free of cracks, open water, empty drums, etc., and the debris between the gaps should be removed before filling and wetted with water. Gap, etc., and the construction environment temperature should be 25 °C ~ 35 °C, too cold or too hot is not good.

3. If cement-based adhesives are used to bond ceramic thin bricks during construction, the adhesive should be evenly combed with a tooth-shaped trowel, and the teeth should be full and clear. The thickness of the adhesive should be 1.0-1.5mm, and the use of wooden poles, rubber rakes, etc. Tap to make tile and adhesive more secure and excess adhesive should be removed immediately.

With regard to the construction technology of ceramic sheeting , I will introduce it here. I hope to help you, and I would like to look forward to more information on this site.

Ceramic Plate Ceramic Bathroom Cabinets Europe and the United States Ceramic Ceramics Electric Saucepan Ceramics