Common bearing steel AISI52100 (GCr15), stainless steel AISI440 (9Cr18), silicon nitride (Si3N4) and zirconia (ZrO2) bearing performance comparison of four kinds of bearing materials, ceramic bearings as an important mechanical basic parts, due to its metal bearing Incomparable superior performance, high temperature resistance, super strength, etc. are playing a leading role in the world of new materials. In the past decade or more, it has been increasingly used in various fields of national economy and people's livelihood. Many people may not be very familiar with ceramic bearings , it is because they do not understand it will be of interest. Don't worry, today I will introduce the use of ceramic bearings, ceramic bearings, cost-effective, to help friends in this area can further understand the ceramic bearings .

Ceramic Bearings Introduction

Ceramic bearings are developed for the adjustment, heavy load, low temperature, and no lubrication conditions in the harsh environment of the defense industry. They are the perfect combination of new materials, new processes, and new structures. By transforming it into a civilian technology, ceramic ball bearings can completely cover all application areas of today's precision, mid-speed and above all-steel bearings. The dimensions of ceramic bearings such as inner diameter and outer diameter are all standard sizes of P4, P5 and P6 grades of steel bearings formulated by the State. Due to the low coefficient of thermal expansion of ceramic materials, low heat transfer performance, and small elasticity, installation and coordination require attention.

Ceramic bearing advantages

First, since ceramics are hardly corroded, ceramic rolling bearings are suitable for operation under harsh conditions filled with corrosive media.

Second, since ceramic rolling balls have a lower density than steel and a much lighter weight, the eccentricity of the outer ring during rotation can be reduced by 40%, and the service life is greatly extended.

Third, ceramics are less affected by thermal expansion and contraction than steel, and therefore allow bearings to operate in environments where the temperature difference changes drastically when the bearing clearance is constant.

Fourth, because the elastic modulus of ceramics is higher than that of steel, it is not easy to deform when subjected to stress, which helps to increase the working speed and achieve high accuracy.

Ceramic bearing applications

Ceramic bearings have high temperature resistance, cold resistance, wear resistance, corrosion resistance, anti-magnetic insulation, oil-free self-lubricating, high speed and other characteristics. It can be used in extremely harsh environments and special conditions. It can be widely used in aviation, aerospace, marine, petroleum, chemical, automotive, electronic equipment, metallurgy, electric power, textiles, pumps, medical devices, scientific research, and national defense military. High-tech products for new materials applications.

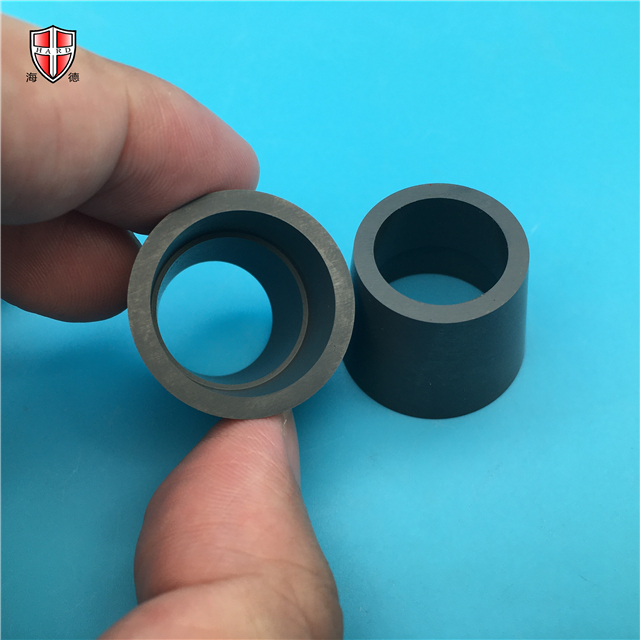

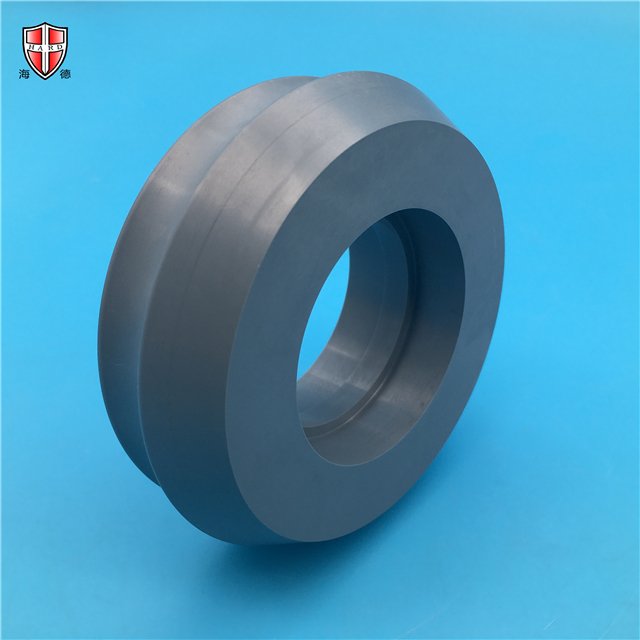

The ceramic bearing rings and rolling elements are made of all-ceramic materials, including zirconia (ZrO2), silicon nitride (Si3N4) and silicon carbide (Sic). The retainer is made of Teflon, nylon 66, polyetherimide, zirconia, silicon nitride, stainless steel or special aviation aluminum, thereby expanding the application surface of ceramic bearings.

Ceramic Bearing Applications

Medical equipment, cryogenic engineering, optical instruments, high-speed machine tools, high-speed motors, printing machinery, food processing machinery.

In the fields of aerospace, navigation, nuclear industry, petroleum, chemical industry, textile industry, machinery, metallurgy, electric power, food, locomotives, subways, high-speed machine tools and scientific research and defense military technology, high temperature, high speed, cryogenic, flammable, Explosive, strong corrosion, vacuum, electrical insulation, non-magnetic, dry friction and other special working conditions, the indispensable replacement of ceramic bearings is gradually understood by people.

With the continuous advancement of processing technology and the ever-increasing level of technology, the cost of ceramic bearings has been declining. It has only been applied in small, high-precision and high-tech areas in the past, and has been gradually extended to various industrial sectors of the national economy. Also gradually approaching practicality, to the extent acceptable to users, the wave of large-scale application of ceramic bearings has emerged!

Ceramic bearing cost performance

The performance-cost ratio of ceramic bearings is much better than that of all-steel bearings. The service life of the ceramic bearings can be increased by more than 3 times than that of the bearings used today, which can save a lot of downtime, reduce the scrap rate, and reduce spare parts for spare bearings. Compared with the performance of the bearing steel, the self-weight is 30% to 40% of the bearing steel, which can reduce the increase of the dynamic load generated by centrifugal force and slip. Because of its high wear resistance and rotation speed 1.3-1.5 times that of bearing steel, it can reduce damage to the channel surface caused by high-speed rotation. The elastic modulus is 1.5 times higher than the bearing steel. The low elasticity of the force can reduce the deformation caused by the high load. Hardness is 1 times that of bearing steel, reducing wear. Compression is 5-7 times that of bearing steel. The coefficient of thermal expansion is less than 20% of the bearing steel. The friction coefficient is less than 30% of the bearing steel, which can reduce the heat generated by the friction, and can reduce the premature failure of the bearing due to high temperature. Tensile, bending and metal equivalent.

Editor's summary: The above is the use of ceramic bearings, ceramic bearing how the relevant price, I hope to help meet the needs of friends! For more information, please continue to follow our website. You can also purchase more of your favorite products on Qijia Mall!

Ceramic Bathroom Cabinets Europe and the United States Ceramic Ceramics Electric Cooker Ceramic Variety Ceramic Mop Pool